Step 1 – Lay out the gutter section:

Place the curved gutter section flat on the ground with the open side facing up. (can be measured in situ)

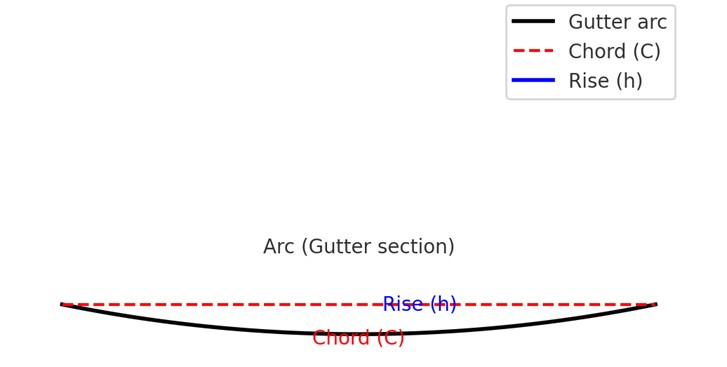

Step 2 – Measure the Chord (C):

Stretch a string/cord tightly between the two ends of the gutter section. Measure this straight-line distance with a tape measure. This is the Chord (C).

Step 3 – Measure the Rise (h):

At the midpoint of the chord, measure from the cord down to the deepest part of the gutter arc. This is the Rise (h).

Step 4 – Calculate the Radius (R):

Use the formula:

R = (C² / 8h) + (h / 2)

Example:

If the chord (C) = 1000 mm and rise (h) = 50 mm:

R = (1000² / (8 × 50)) + (50 ÷ 2) = 2525 mm ≈ 2.5 m

Record your results:

Chord (C) = ______ mm

Rise (h) = ______ mm

Radius (R) = ______ mm (or m)

Tuscan Foundry Products specialises in traditional cast iron rainwater systems, with a particular focus on bespoke and radiused guttering solutions. From curved bays and turrets to complex period restorations, we provide custom-made guttering cast to precise radii, ensuring an authentic fit for heritage and architectural projects. Every section is carefully designed to match existing profiles or meet conservation requirements, with the durability and character of cast iron. Our work spans churches, listed buildings, and unique architectural projects across the UK, where accuracy, craftsmanship, and attention to detail are essential.

Radiused guttering is cast iron guttering made in a curve, designed to follow round or angled features such as turrets, bays, or curved walls. Unlike standard straight lengths, these gutters are cast to a specific radius, ensuring a snug fit against the building. Tuscan Foundry Products supplies bespoke radiused sections to match your building’s needs.

To measure, you need two things:

The profile size (e.g. 115mm half-round).

The building radius (the curve the gutter follows).

You can measure the radius using a tape measure and string (chord and rise method) or by providing Tuscan Foundry Products with a template taken from the building. We can also advise on the best approach if access is difficult.

Most standard cast iron profiles can be supplied in a radius, including:

Half-round

Beaded half-round

Ogee and moulded sections

Tuscan Foundry Products will confirm whether the profile and radius required can be cast.

Because every job is bespoke, radiused cast iron guttering requires longer lead times than standard stock lengths. At Tuscan Foundry Products, we usually advise allowing 12–14 weeks from confirmation of details to delivery.

Yes. Radiused guttering requires special pattern-making and casting, which results in a higher cost per metre compared to standard straight lengths. The price depends on the profile, radius, and quantity. Tuscan Foundry Products will provide a precise quotation once we have your measurements or template.

Absolutely. It’s common to have straight runs leading into curved sections around bays or turrets. Tuscan Foundry Products can supply both, ensuring the joints and profiles match perfectly for a seamless installation.

Yes. If required, Tuscan Foundry Products can offer advice on site measurement or review templates you provide. In complex projects, we can arrange a site visit to ensure the correct radius and profile are supplied.