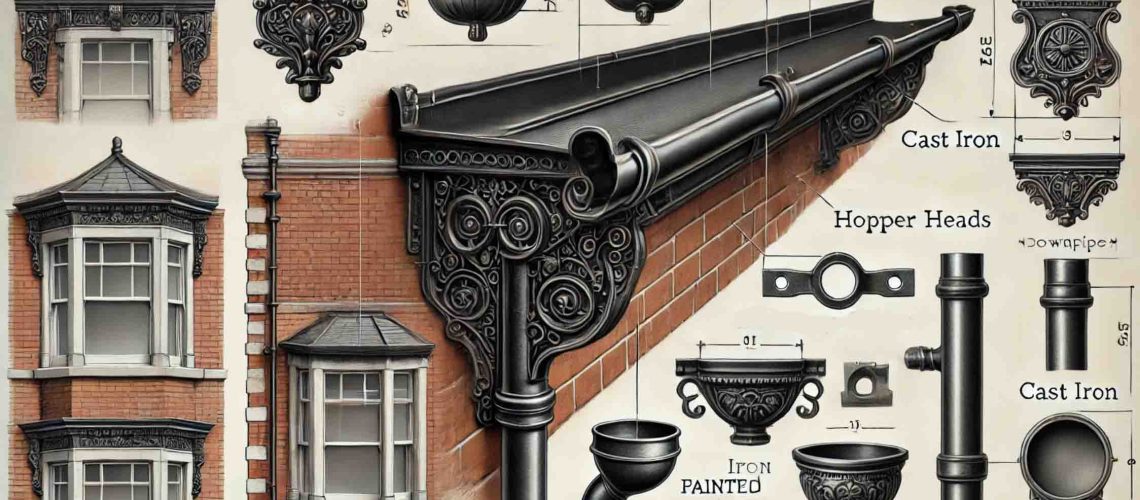

The Industrial Revolution saw the advent of the first mass-produced gutter and pipe systems crafted from cast iron. However, during the Victorian era, cast iron rainwater systems took on decorative design features, showcasing the aesthetic potential of cast iron on building exteriors. Before this innovation, gutters were often made from lead or timber—materials that can still be seen today in preserved or restored historic structures. Local foundries across the UK produced cast iron pieces with unique shapes and profiles, some even specific to regional styles, such as the iconic Notts Ogee profile.

The original method for casting in iron, known as “green sand” floor moulding, involved a wood pattern that created male and female sand moulds. Molten iron was poured into these moulds, cooling and solidifying to the desired shape. The casting was then extracted and finished with a bitumen-based paint to provide weather resistance. Today, Tuscan Foundry Products continues to employ these time-honoured techniques to create bespoke rainwater systems, preserving the craftsmanship and charm of Victorian-era designs.

Cast iron has experienced renewed popularity, driven by a focus on heritage conservation and sustainable building practices. This versatile material is highly favoured for restoration projects and high-end traditional construction. Architects and property managers appreciate cast iron’s durability, aesthetic appeal, and sustainability for buildings ranging from historical sites and churches to residential homes and municipal structures. As a trusted name in cast iron rainwater goods, Tuscan Foundry Products ensures each piece is crafted to meet the rigorous standards of traditional and conservation-grade projects.

Cast iron remains a top choice for rainwater systems due to its enduring strength, versatility, and low environmental impact. Tuscan Foundry Products uses a mix of recycled materials—including scrap iron and steel—to manufacture cast iron goods that are 100% recyclable at the end of their life cycle. These qualities make cast iron ideal for projects prioritising sustainability without compromising heritage or aesthetics.

With a comprehensive range of cast iron gutter profiles, Tuscan Foundry Products replicates historical designs while adhering to modern standards.

Available profiles include Half Round, Beaded Half Round, Victorian Ogee, Notts Ogee, Deep Half Round, G46 Moulded, and Box gutters in various sizes. Pipe options also come in round, square, and rectangular sections, ensuring compatibility with diverse architectural needs.

uscan Foundry Products offers both primed and pre-painted options for cast iron components. Pre-painted products come in a selection of British Standard and RAL colours to meet specific planning or aesthetic requirements. The mechanised coating process ensures a uniform thickness and excellent finish quality, while pre-painted options enable faster installation. Linseed oil hand paint finishes, noted for their durability and resistance to sunlight and corrosion, offer exceptional colour retention suitable for harsh outdoor environments, and a period feel.

When opting for primed components, on-site painting should be thorough, covering all visible and hidden areas to ensure maximum protection. Painting must be thoroughly dried before installation to prevent silicone sealant reactions, as Tuscan Foundry Products recommends.

For heritage and bespoke restoration projects, Tuscan Foundry Products specialises in custom rainwater goods such as ornamental hopper heads, curved or radius gutters, and unique gutter profiles. Through traditional sand-casting methods, the company recreates intricate designs that blend seamlessly with historical buildings. Our skilled team can assist with project-specific requirements to ensure the best solutions for sensitive restorations.

Cast iron gutters are typically supported by fascia brackets attached to the timber fascia or directly fixed with corbel stone or brick support. Tuscan Foundry Products supplies compatible rise and fall, and rafter brackets for situations

without fascia boards, ensuring a secure fit regardless of building type.

Pipes are secured using eared sockets, ear bands, or independent brackets known as holderbats. Proper installation requires the use of recommended fixings to maintain both support and longevity.

Traditionally, putty was used for gutter joints, but modern installations favour low-modulus silicone sealants for their improved adhesion and durability. Tuscan Foundry Products also offers dry-jointing systems with rubber seals, allowing for quicker, reliable assembly in half-round profiles.

In many historic buildings, BS416-grade cast iron pipes are specified for rainwater and soil and vent applications to maintain visual and structural integrity. For interior use, Tuscan Foundry Products provides cast iron systems with rubber-sealed, bolted compression joints meeting BS EN 877 standards.

Tuscan Foundry Products proudly stocks a complete range of cast iron rainwater systems for nationwide distribution, supporting local trades and online orders. Our products are crafted to exacting standards, meeting the needs of heritage conservation, traditional builds, and modern sustainable projects alike.

At Tuscan Foundry, we understand that meticulous planning is the foundation of any successful restoration or conservation project. Our estimating and surveying services provide invaluable insights into the unique characteristics of period and listed buildings. Our experts accurately assess project requirements through detailed site visits, ground surveys, and aerial platform inspections. We offer precise cost estimates, material recommendations, and bespoke solutions to ensure seamless integration with historical architecture while maintaining structural integrity.