That approach gives better control, keeps everything square, and avoids stress on joints and brackets.

That said, there are situations where working top down makes sense. The key is understanding what is fixed, what can move, and where gravity will try to take over.

In practice:

Shoe → first straight → offset (if any) → continue up → final connection into hopper or gutter outlet.

If the hopper, eaves outlet, or gutter socket cannot move, it may be sensible to start there so the connection is perfect.

This is more common:

If you’re only replacing:

Then you may need to work between two fixed points, easing pipes apart from above and below.

On tall soil stacks:

Even here, the final alignment check usually references the bottom.

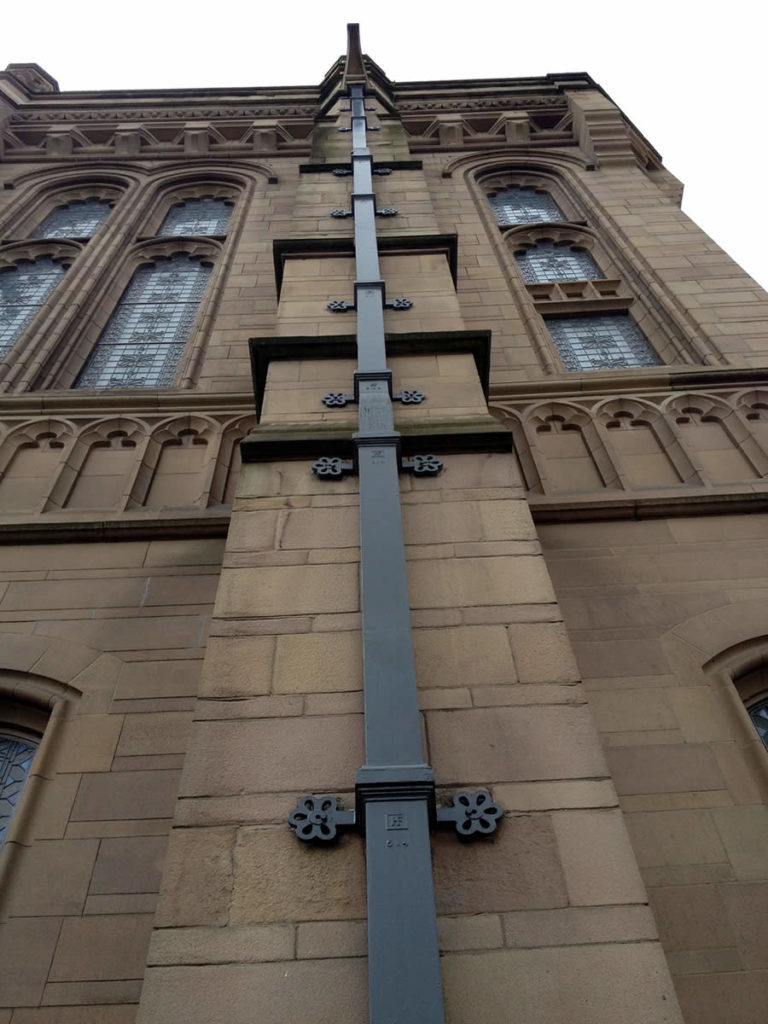

Cast iron pipes are supplied with sockets, either plain or with fixing ears. These ears allow direct attachment to walls, offering extra stability.

Pipe Sockets

Fixings Overview

Pipe Nails

Coach Screws

Brackets and Holderbats

Pipe Jointing Compounds

Silicone Sealant

CT1 Sealant

Caulking Cord

Avoid the following:

If the shoe position matters (which it usually does): go bottom up.

If the top connection is absolutely fixed and untouchable: consider top down, with care.

At Tuscan Foundry Products, we understand that every project is different. Whether you’re installing a full cast iron rainwater system or replacing a section of heritage pipework, knowing when to work from the bottom up (or top down) can make all the difference. We supply sockets (plain or with ears), traditional and decorative fixings, and all the jointing compounds you need for a long-lasting installation.

Visit our Cast Iron Rainwater Pipes page for more details and product support.