Cast iron is a popular choice in the construction and exterior ornament sectors due to its resilience and durability. There are several types of cast iron, dependent upon its chemical composition, which can also include traces of sulphur, manganese and phosphorous, as well as the main components of iron, carbon (2-5%) and silicon. The higher carbon content in comparison to steel means it has several unique properties:

Cast iron is significantly stronger than many alternative materials thanks to its high carbon content, which enhances its hardness and load-bearing capability. Although it is hard, brittle, and non-malleable, these properties contribute to its excellent compressive strength, allowing it to perform well under heavy static loads. While its tensile strength is relatively low compared to modern alloys, its rigidity and stability make it a preferred material for applications where dimensional accuracy and structural integrity are vital, such as architectural castings and drainage systems.

Cast iron is non-porous, watertight, and exceptionally resistant to erosion, making it ideal for long-term external use. It can endure extreme weather conditions — from heavy rain and frost to high temperatures — without losing its shape or function. Its robustness and low maintenance needs make it a reliable material for traditional rainwater goods, pipework, and decorative architectural components that are expected to last for decades with minimal upkeep.

Cast iron possesses outstanding heat retention and distribution qualities. Once heated, it maintains a steady, even temperature over extended periods, which is why it remains a preferred material for cookware, radiators, and architectural applications that benefit from thermal stability. This ability to store and release heat gradually contributes to its efficiency and reliability in both domestic and industrial environments.

Cast iron is naturally resistant to corrosion due to a dense oxide film that develops on its surface during the casting process. This protective layer limits moisture penetration and slows oxidation, offering superior corrosion resistance compared with mild steel or wrought iron. When properly painted or treated, cast iron can provide outstanding longevity, making it especially well-suited to exposed architectural and drainage applications in historic and modern buildings alike.

The high density of cast iron enhances its ability to absorb vibrations and dampen sound, reducing noise in mechanical and structural applications. This characteristic makes it particularly valuable in buildings, pipe systems, and machinery installations where vibration control contributes to comfort, stability, and extended service life. Its natural sound-deadening properties also make it a material of choice for traditional rainwater systems and architectural fittings in both period and contemporary settings.

These factors all contribute to the lengthy lifespan of cast iron, which is approximately 100 years with appropriate maintenance.

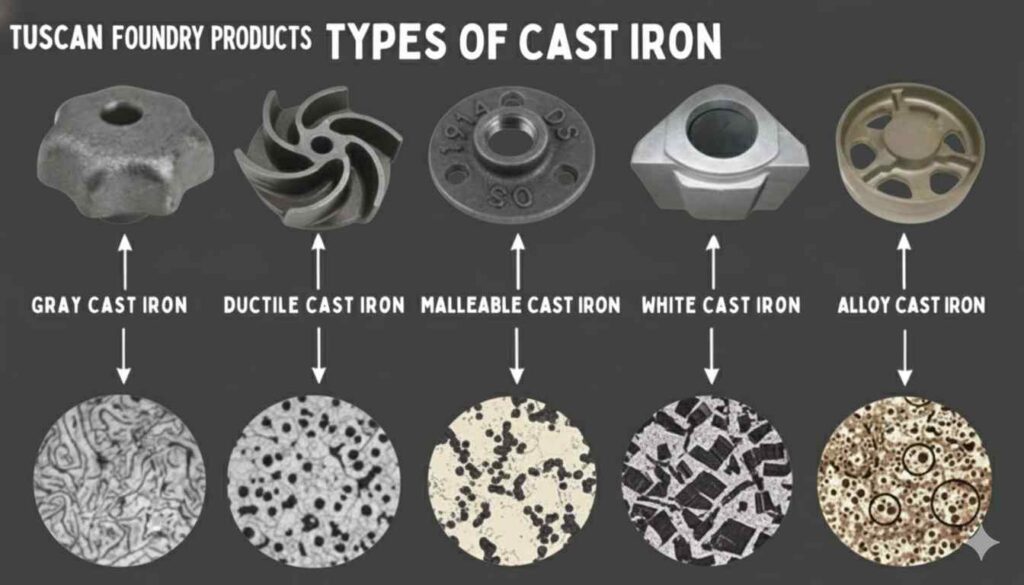

Ease of casting makes grey cast iron the most commonly used. It is less malleable and has a lower tensile strength than white cast iron, which is favoured for its abrasion resistance. Other types include ductile cast iron (more tensile, tough and ductile) and malleable cast iron (more ductile and less brittle).

Microstructure of the different types of cast iron (from Cast Iron: Definition, Properties, and Uses by the Engineering Choice).

Finishes such as bituminous coatings, waxes, paints, galvanising, and plating can reduce corrosion caused by climatic factors (the presence of atmospheric humidity and oxygen).

Tuscan Foundry Products uses linseed oil, as discussed in a separate article.

(Linseed oil coating (Tuscan Foundry Products).

Cast iron is used structurally and decoratively, with typical uses including columns, balusters, fences, stoves, piping, hardware and structural connectors. Its unique properties, as well as its heritage aesthetic, make it a popular choice for renovations and the conservation of historical buildings.

Increased rainfall can cause stress to drainage and guttering. Blockages from debris such as leaves, dirt and sediment prevent the water from draining effectively. This, in turn, can cause flooding, damp issues, and the bending or cracking of guttering. Increased pressure and erosion contribute to leaks and weakening of the structural integrity of gutters, drainage pipes and hopper heads.

Cast iron is robust and durable when used appropriately and protected from adverse exposure. It is much stronger in compression than in tension; therefore, it is commonly found in columns, but not in structural beams. It is, however, highly susceptible to corrosion (rusting) when exposed to moisture, and it has several typical problems which can usually be identified by visual inspection. The following sections will identify and discuss the most common issues encountered with cast iron. For general guidance on inspecting for cast iron failures, see 05010-01-G.

The typical deterioration or corrosion process for cast iron is a one-step, straight-line oxidation (or rusting) that begins upon exposure to air and moisture and continues (unless interrupted) until the metal is gone. This process is described in the following section.

Rusting, or oxidation, is the most frequent and easily recognisable form of cast iron deterioration. Cast iron is highly susceptible to rusting when the humidity exceeds 65%. Iron (Fe) combines with oxygen (O) in the presence of water vapour (H2O) to become rust (Fe2O3). This process can take place at significantly different rates depending on the material composition, the protective treatments applied, and the severity of exposure. If rusting occurs rapidly, it can cause severe damage or the total loss of a component in a short time; therefore, the presence of any rust on a cast iron artefact should alert the observer to a serious problem. Rusting can occur even at humidity as low as 58% in the presence of certain pollutants, such as sulphur dioxide, ammonia sulphates, or body oils from contact. Reducing humidity to 30% or lower is effective at preventing rust; however, it is not a practical solution for outdoor cast iron.

Rusting is so common that it is easily recognisable. Rust (Ferrous Oxide, Fe2O3, and Ferric Oxide, Fe3O4) is an orange-coloured surface coating that ranges in texture from scaly to powdery. It is loosely bound, and the outer layers will usually come off when rubbed by hand or brushed against. It is not a deposit on the surface. Rust is the result of the combination of iron (Fe) with oxygen (O) in the air, in the presence of moisture. The presence of rust indicates that some of the original iron has been converted to iron oxide and irreversibly lost from the cast iron piece.

The probability of rust occurring is generally dependent upon two factors:

Protective coatings used on iron include bituminous coatings (such as tars), waxes, paints and sophisticated metallic coatings. Effective coatings, well-maintained, provide the most reliable protection against rust and corrosion of cast iron; however, there is a wide variety of coatings available, and these can be confusing to users not thoroughly versed in the technical data for each type.

Humidity is the second factor affecting the rate of oxidation (rusting) of iron. It is generally accepted that rusting cannot begin unless the relative humidity is at or above 65% (this figure can be lower, however, in the presence of pollutants). Relative humidity is, however, not the only factor to be considered. Once rusting has started, at least two other phenomena may occur:

Both of these conditions are microscopic in nature and invisible to casual inspection. Maintenance staff and trained personnel, however, should be aware of the processes and the potential for the processes to damage the cast iron.

The presence of visible rust indicates a problem. Appropriate action should be taken to prevent rusting, and where it does occur, to correct it with a proper treatment. See individual repair or preventive maintenance procedures for specific guidance as needed.

Many other factors can affect both corrosion and its rate. Sea water, salt air, cements, plasters, ashes, sulphur, soils and acids can accelerate the corrosion of iron. Corrosion rates can also be accelerated when the detailing of the cast iron creates pockets that can collect and retain moisture and corrosive agents. Preventive maintenance plans should consider detailing, such as crevices and recessed areas, when establishing routine inspection techniques and inspection frequency.

Cast iron contains carbon, in the form of graphite, in its molecular structure. It has a crystalline structure, as do all metals, i.e., it is a heterogeneous mass of crystals of its major elements (Iron, Manganese, Carbon, Sulphur and Silicon). One condition which can occur in the presence of acid rain and/or seawater is “graphitisation.” The stable graphite crystals remain in place, but the less stable iron becomes converted to insoluble iron oxide (rust). The result is that the cast iron piece retains its shape and appearance but becomes mechanically weaker due to the loss of iron. Graphitisation, however, is not a common problem. It generally occurs only after bare metal is left exposed for extended periods, or when failed joints allow acidic rainwater to penetrate interior surfaces.

This corrosion process is galvanic, with the carbon present acting as the most noble (least corrosive) element and the iron acting as the least noble (most corrosive) element. The composition or microstructure of the iron affects the durability of the object because the rate of corrosion is dependent upon the amount and structure of the graphite present in the iron.

Barrier coatings are the most commonly used protective mechanisms for cast iron. Some coating (such as a wax, paint or metallic coating) should probably be considered an integral feature of cast iron in service. The absence of such a coating, or a failure in an existing coating, should be corrected. Inspection should include a visual examination of all surfaces to determine whether a coating exists, a fact that may be very apparent for opaque paints and coatings but substantially less apparent for transparent lacquers, waxes, or oils. Surfaces that appear to be raw metal should be carefully examined for signs of rust. The absence of a coating should be considered a significant problem, and corrective action should be undertaken. See individual repair or preventive maintenance procedures for specific guidance as needed.

Failure of a coating should also be identified and corrected. Coatings can wear away, crack, flake, blister, or peel away, indicating that the coating has failed and is no longer protecting the cast iron from moisture. Failed coatings can, in fact, trap moisture beneath the film and accelerate corrosion at specific points on the surface. Inspection of the surface should include a careful check for all of these types of coating failures. A record should be made of any coating failures observed so that corrective action may be taken.

Mechanical failures in cast iron are typically of two types and are relatively common.

Structural Failure:

Cast iron may contain various imperfections due to the manufacturing process. These may occur due to air holes, interrupted pouring, uneven cooling (cold sheets), cracks and cinders. Where such imperfections occur, the piece may be weakened mechanically, sometimes severely. These manufacturing problems are not generally visible upon inspection; however, several non-destructive techniques can be used to identify them, such as fluorescent fluids and ultraviolet lamps, or X-ray inspection. These non-destructive techniques require specialised knowledge and equipment and are generally not feasible for maintenance staff to use. Specialists with experience should undertake them.

Visible inspection, however, may enable detection of mechanical failures after they have occurred or are beginning to occur. Stress cracks in paint or metal may be symptomatic of this problem. Failures may begin as gradual separations which are visible upon inspection and may be detected and corrected before a total, catastrophic failure of the piece. Linear cracks in paint film or metal should be investigated and/or monitored to determine if they are active. Non-destructive techniques may be used if symptoms exist. Still, the Regional Historic Preservation Officer (RHPO) should be consulted when soliciting professionals experienced in the use of these techniques.

Mechanical Failure of Connections:

Larger cast iron pieces are generally systems composed of smaller castings, mechanically connected. This can even be the case for a simple baluster or historical marker. One of the most common failures in such systems is a connector or joint failure. Loose, missing, or broken screws, clamps, or bolts may result in loose, failed, or missing components. Visual inspection should include examining cast iron pieces for loose or misaligned sections, and for loose or missing screws or bolts. Further manipulation by hand, with probes, may indicate whether a casting is a discrete piece, mechanically attached, and whether or not it is in the early stages of working loose. It is crucial to detect connectors that are at risk of imminent failure if left uncorrected. Corrective action should be undertaken in either case. Still, the treatment plan should take into account the severity of the problem, the consequences of failure, and the nature of the intervention required to correct it. See individual repair procedures for specific guidance as needed.

Inappropriate mechanical repairs to broken pieces can cause another mechanical problem. Some repairs may create openings that allow water penetration and “pockets” that collect water, both of which can cause problems. Castings filled with concrete are also a potential problem, as they may promote “crevice corrosion” due to entrapped water. Visual inspections should check for such conditions, and where they exist, maintenance staff should plan to correct the problems and/or be vigilant for signs of deterioration.

Cast Iron Alloys for Replacements

Cast iron problems, especially corrosion problems, may be reduced or eliminated in cast iron that is an alloy of silicon, nickel, chromium and/or copper. For example, silicon is often present in cast iron to some degree. Still, it is not considered an alloy until the percentage exceeds the upper limit of 3% for non-alloy cast iron. Where silicon is present, a protective surface film develops during oxidation.

There are three main categories of cast iron alloys:

All of these alloys, plus copper alloys, have been tested and found to have increased corrosion resistance. The degree of increased resistance is dependent on many factors, primarily the alloying metal and the percentage of alloy relative to the carbon content of the cast iron. While a discussion of alloy durability and formulation is beyond the scope of this standard, users should be aware of the effect of alloying and consider the implications when ordering new cast iron replacement objects. Such consideration may involve experienced metallurgists, foundrymen, conservators, and historical architects.

The maintenance principles for cast iron are, in order of appearance:

Structural iron maintenance may require the services of a structural engineer when severe erosion or distortion occurs, to assist in developing repair techniques when material loss is involved. For these repairs, use only a professional ironworker. Before installing the new material, verify the metal type and thickness. Before installation, remove all oil, dirt, and other debris from the surface. All surfaces shall be dry and free from frost.

About the Author: Eliza Stenning is a Geography student at the University of Edinburgh with a passion for exploring the connections between people and landscapes. When she’s not studying or writing, she loves hiking, camping, travelling, and spending time in the wilds.

At Tuscan Foundry Products, we don’t just supply cast iron products—we breathe life back into heritage through meticulous restoration, thoughtful design, and expert craftsmanship. Our detailed knowledge of cast iron’s unique properties—its compressive strength, durability, heat retention, and corrosion resistance—guides every project we undertake. Whether you’re conserving a Georgian townhouse or revitalising a Victorian civic building, we understand the historic and architectural demands involved.

From the careful casting of bespoke gutter profiles and rainwater hopper heads to precision site surveys and aerial inspections, Tuscan Foundry brings over a century of experience to every detail. Our skilled team works closely with architects, conservation officers, and heritage property owners, offering tailored advice and custom solutions—right down to exacting colour matches using traditional linseed oil paints for longevity and authenticity.

Every bracket, joint, and pipe we manufacture is designed not only to meet structural and environmental challenges but also to honour the visual legacy of the past. Our capabilities include:

Recreating historical rainwater systems from original patterns or photographs

Conducting on-site assessments to determine structural needs and flow rate calculations

Supplying hand-finished cast iron fittings compatible with listed building requirements

Delivering bespoke castings for architectural features beyond drainage systems, including ornamental elements and pavement lights

With each project, we combine traditional techniques with modern precision to ensure the lasting performance and historical integrity of cast iron in the built environment. For those looking to preserve the past without compromising quality or authenticity, Tuscan Foundry stands as a trusted partner in conservation.

Let us help protect your building’s legacy—one bracket, pipe, and hopper head at a time.