In the conservation and restoration of period properties, attention to detail is paramount—especially when specifying rainwater goods. One such detail, often underestimated, is the calculation of pipe offsets and swan neck dimensions to ensure that cast iron downpipes align accurately with sub-surface drainage infrastructure.

At Tuscan Foundry, we understand the importance of both heritage accuracy and functional precision. This guide will support professionals in specifying the correct components for their cast iron rainwater systems—be it for listed buildings, conservation areas, or traditionally styled new developments.

Downpipes must connect precisely with the below-ground drainage or gully, yet in many period buildings, the gutter outlet is not vertically aligned with this point. This misalignment may be due to:

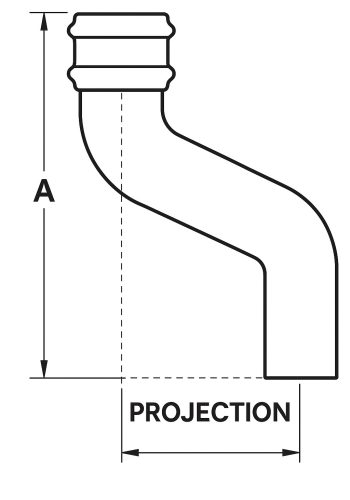

To bridge this gap and ensure a continuous, watertight path for rainwater, offsets—often referred to as swan necks—are introduced.

Determining Your Offset Projection

The key measurement required is the horizontal distance between the centreline of the gutter outlet and the centreline of the intended downpipe run. This is known as the projection.

For accuracy:

Unlike modern materials that allow on-site adjustment, traditional cast iron downpipes are cast with fixed offset dimensions. As such, precise planning is essential to avoid on-site complications.

Tuscan Foundry offers a selection of fixed offset sizes to accommodate common architectural requirements:

Bespoke sizes can also be manufactured to suit complex or non-standard installations.

Correct pipe alignment is essential for both performance and visual integrity:

Square/Rectangular Pipes:

Due to their geometry, square and rectangular pipes cannot be rotated to achieve alignment, so precise ordering is crucial.

Round Pipes:

Tuscan Foundry Products provides site surveys, CAD drawings, and bespoke casting services to ensure every component is manufactured for a precise fit. When required, we also fabricate custom offsets to suit complex or heritage-specific requirements.

Offset calculations may appear minor, but in heritage and conservation work, precision in rainwater system design can make the difference between a seamless installation and a costly rework. Whether you’re restoring a Georgian townhouse or specifying pipework for a converted chapel, Tuscan Foundry’s expertise in cast iron rainwater goods ensures your project maintains both its function and historic integrity.