Cast iron has been used for centuries and was used in architecture in the pre-modern period, the 13th century Indian “Konark Sun Temple” using iron beams to support its structure.

Cast iron was first used in pagoda construction in Tang Dynasty China. Texts by the Japanese Buddhist monk Ennin describe in detail the cast-iron pagodas and statues widespread in China during the 9th century.

The first time cast iron was used in framing a building was the Ditherington Flax Mill, built in 1796, considered the first iron-framed building in the world. Cast iron has immense compressive strength and was successfully used for certain structural components in bridges and buildings.

The 18th-century Britain brought new production methods allowing cast iron to be produced cheaply enough and in large enough quantities to be used in larger building projects. The new production methods, using a steam engine powered blast air, which allowed higher blast furnace temperatures. The higher furnace temperatures also increased the furnace capacity.

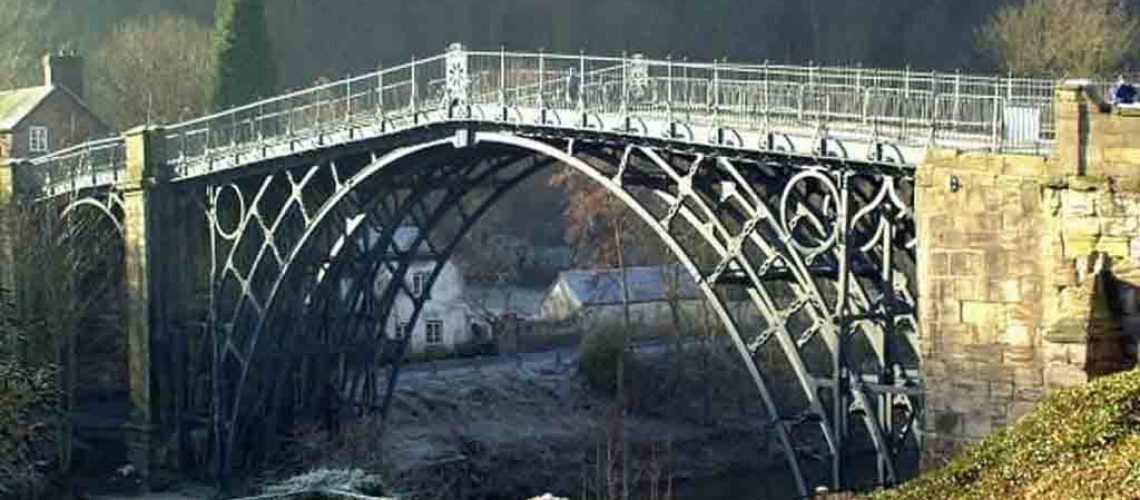

Alongside the great successes of cast iron construction, there were also some epic failures, caused by cast irons low tensile strength but experience and technical developments led to some important projects, including The Iron Bridge in Shropshire. Constructed almost entirely from cast iron, the Iron Bridge was over-designed and engineered, resulting in financial difficulties for Abraham Darby. This construction itself was not without fault, with the low quality of the iron used, some 80 brittle cracks are still visible today.

The engineers, designers and architects were learning and improvements were constantly being made, with later designers, such as Thomas Telford, improving both design and materials, used in

further bridges and canal aqueducts.

Today we use cast iron, on or within, to replicate and provide authenticity to period and historical buildings, with cast iron drainage products, cast iron gutters and pipes, along with cast iron radiators and cast iron air vents and bricks, being some of the components still available.

The strength, durability, and long service life of cast iron components are widely recognized. With the French King Louis XIV ordering the construction of a Cast Iron pipe main extending 15 miles from a pumping station at Marly-on-Seine to Versailles to supply water to the fountains and town. This pipe has served the palace gardens for more than 330 years.

Cast Iron products still have a significant structural, longevity and aesthetic advantage when used in both period and modern buildings, and should always be considered as an alternative to the plastics, steel and aluminium that are now so commonly used.

Cast iron continued to be used in Britain and around the World, with projects, such as the Commissioners House of the Royal Navy Dockyard in Bermuda in the 1820s, the covered Valletta market in Malta, structures and facades in New York and New Orleans, with new iron foundries being created in many countries.

Cast Iron was being used to construct columns, which were slender, when compared to masonry equivalents and, enabled architects of theatres, churches and synagogues to improve sight lines when supporting balconies.

The culmination of cast irons use in construction and architecture came with the building of the monumental Crystal Palace in London in 1851. Designed by Joseph Paxton, the glass-and-cast-iron structure was a development from the greenhouse structures already available and became much imitated around the world.